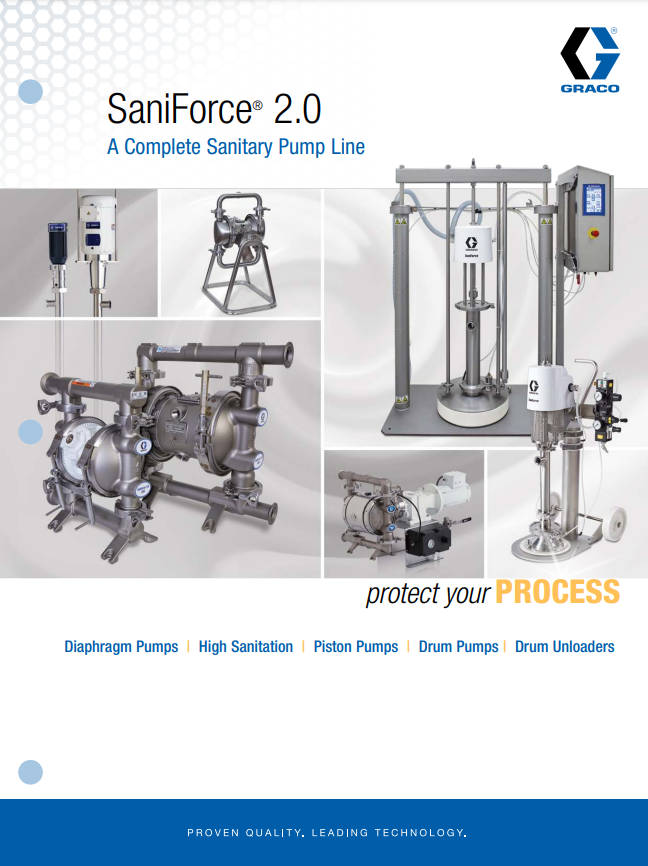

CLEAN-IN-PLACE (CIP) PUMPS

We offer Clean-In-Place (CIP) system pumps suitable for a diverse array of food, beverage, and brewery uses, in addition to other hygienic settings. These pumps are especially well-suited for tasks demanding regular clean-in-place operations. We offer CIP system pumps are designed without exposed metals and can be customized with different materials to fulfill demands for abrasion resistance, temperature variations, and chemical compatibility.

CIP SYSTEM PUMPS FOR FOOD, BEVERAGE AND OTHER SANITARY ENVIRONMENTS

EASY-TO-CLEAN PUMPS FOR CIP SYSTEMS

Most of our pumps designed for sanitary applications feature quick knockdown features for cleaning in place operations. Models are FDA-compliant and can be disassembled in five minutes or less. Ease of cleaning is further enhanced with the pump’s smooth, flat surfaces and no recessed areas where bacteria can hide.

IMPROVE YOUR PROCESSES

Reduce Downtimes

Reliable clean-in-place pumps reduce downtime through regular maintenance. With fewer moving parts, you’ll also reduce repair times.

Long-Lasting, Reliable Equipment

Expect your CIP pumps to last for years of reliable service. Additionally, our field-proven designs are manufactured with the highest quality materials.

BROWSE CLEAN-IN-PLACE (CIP) PUMPS

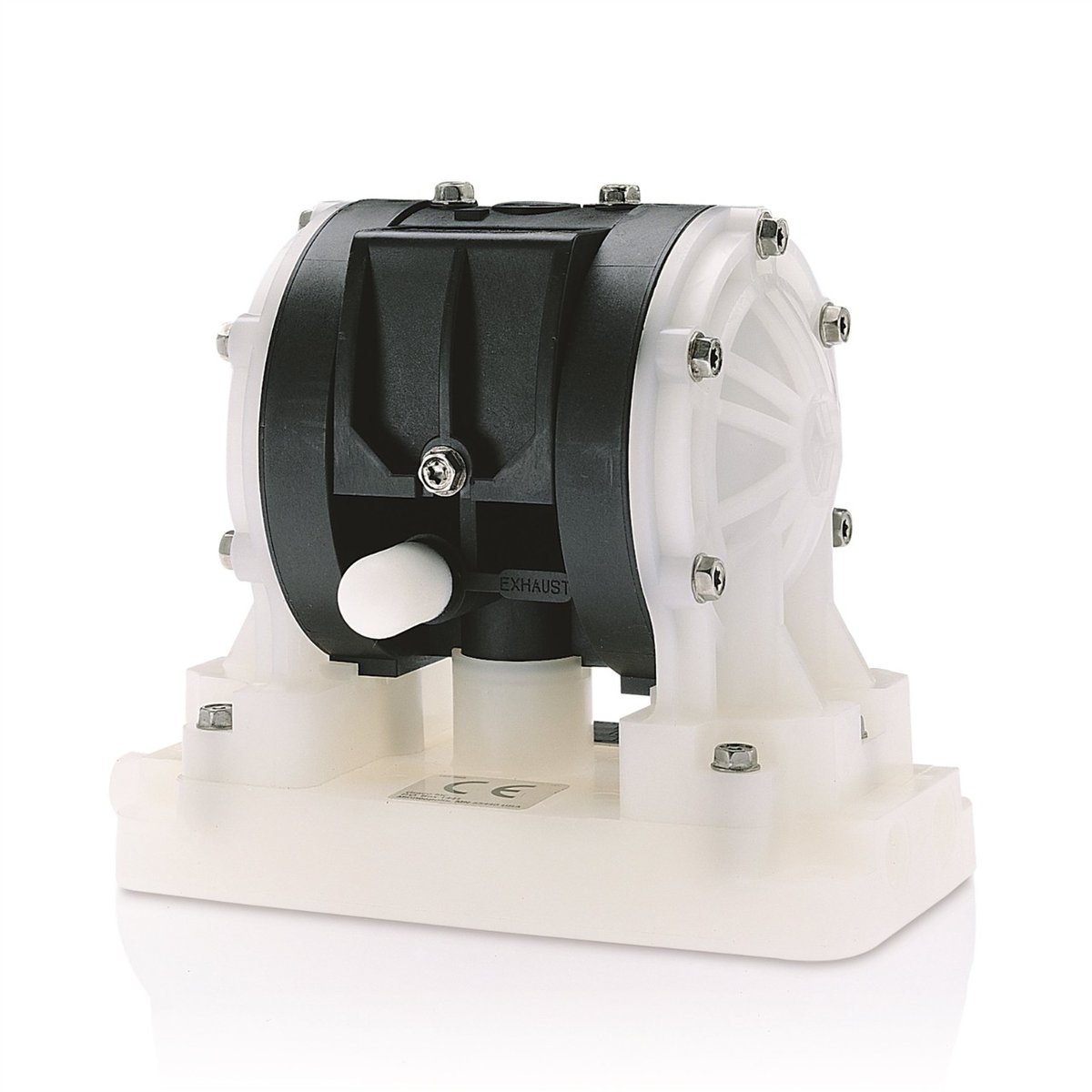

Husky 1050

The Husky 1050 air-operated diaphragm pump boasts a stall-free, low-pulsation air valve, ensuring a seamless and quick transition. Its single-piece center section design not only eradicates leaks but also minimizes maintenance requirements in comparison to alternative diaphragm pumps. With a maximum fluid pressure of 125 psi, it achieves a peak flow rate of 189 L/min. Its inlet/outlet size is 1″, and it is offered with either end or center porting options.

Husky 515

The Husky 515 air-operated double diaphragm pump, renowned for its stall-free low pulsation air valve, ensuring a seamless and swift transition.

The innovative bolt-through fluid cover design not only eradicates leaks but also enhances the safety and reliability of the Husky, setting it apart. It operates at a maximum fluid pressure of 100 psi, delivering a peak flow rate of 56.8 L/min. With an inlet/outlet size of 1/2″, it’s available with convenient center porting.

Husky 307

The Husky 307 air-operated diaphragm pump features a stall-free low pulsation air valve for smooth transition. It’s versatile, used in scenarios like oil and fuel transfer, windshield wash, and UL-approved for gasoline/alcohol blends. Operating at max 100 psi, 24.6 L/min flow rate, 3/8″ inlet/outlet, and end porting.

Husky 205

The Husky air-operated double diaphragm pumps comes brimming with attributes designed to ensure consistent and accurate task completion, every time, all while being crafted to enhance cost-efficiency.

The Husky 205 air-operated diaphragm pump is equipped with spring check valves, enhancing priming efficiency across various mounting configurations. It boasts a maximum fluid pressure of 100 psi, coupled with a flow rate of 18.9 L/min. The pump features end porting and a 1/4″ inlet/outlet fluid porting.

![[IMAGE] Cross X](https://strouds.co.nz/wp-content/uploads/2024/02/X.png)